LEAP 71

@leap_71

We create computational models for engineering to build the world's most advanced machines.

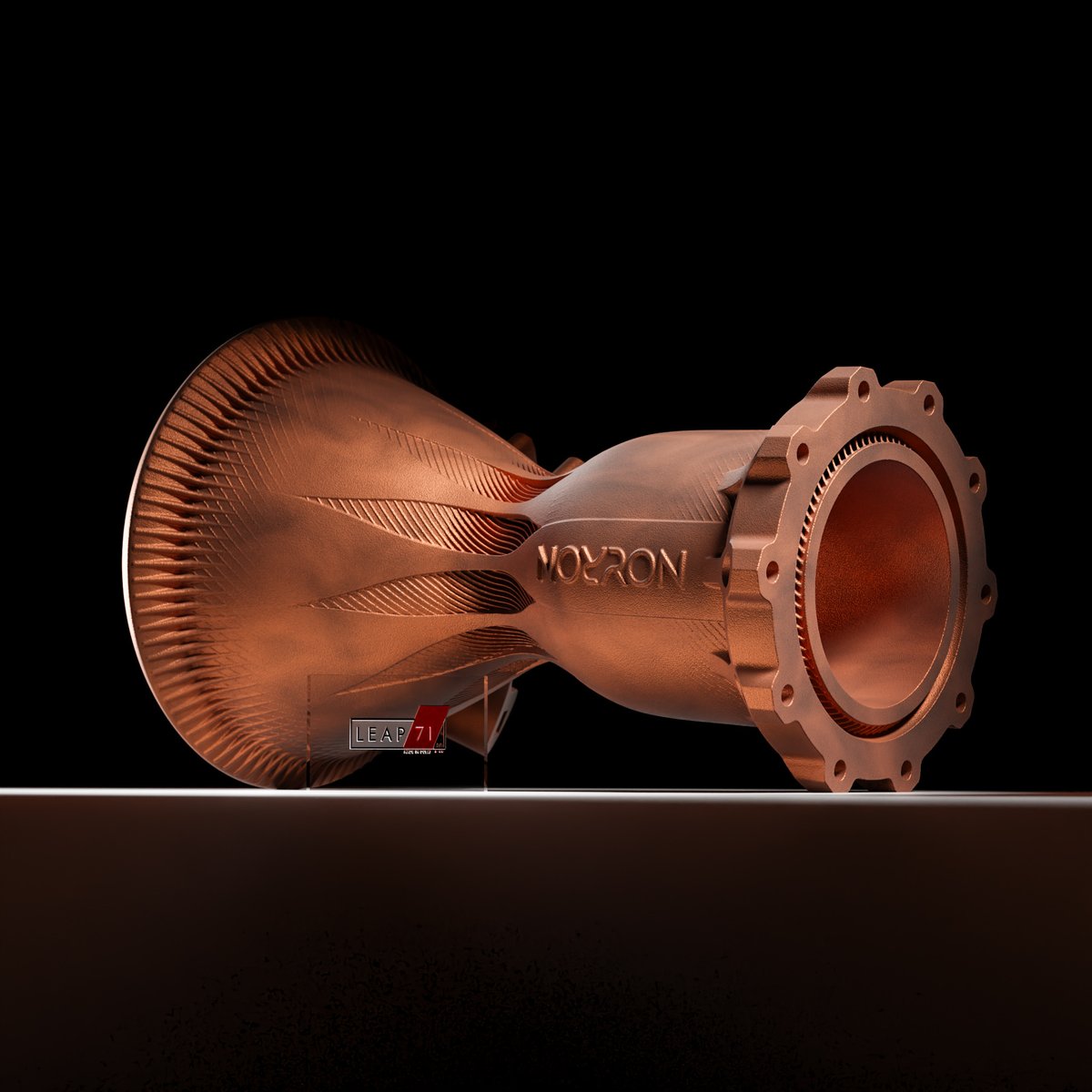

Two compact monolithic 2kN KeroLOX thrusters generated by Noyron. On the left a version with Pintle, on the right an impinging injector. Noyron allows us to quickly swap out the engineering logic and test different variants without manual work.

A compact 2kN KeroLOX rocket engine with a Pintle injector. Pintle injectors have advantages for small engines, especially for the deep throttling required for lunar landers. Generated autonomously by the Noyron Large Computational Engineering Model.

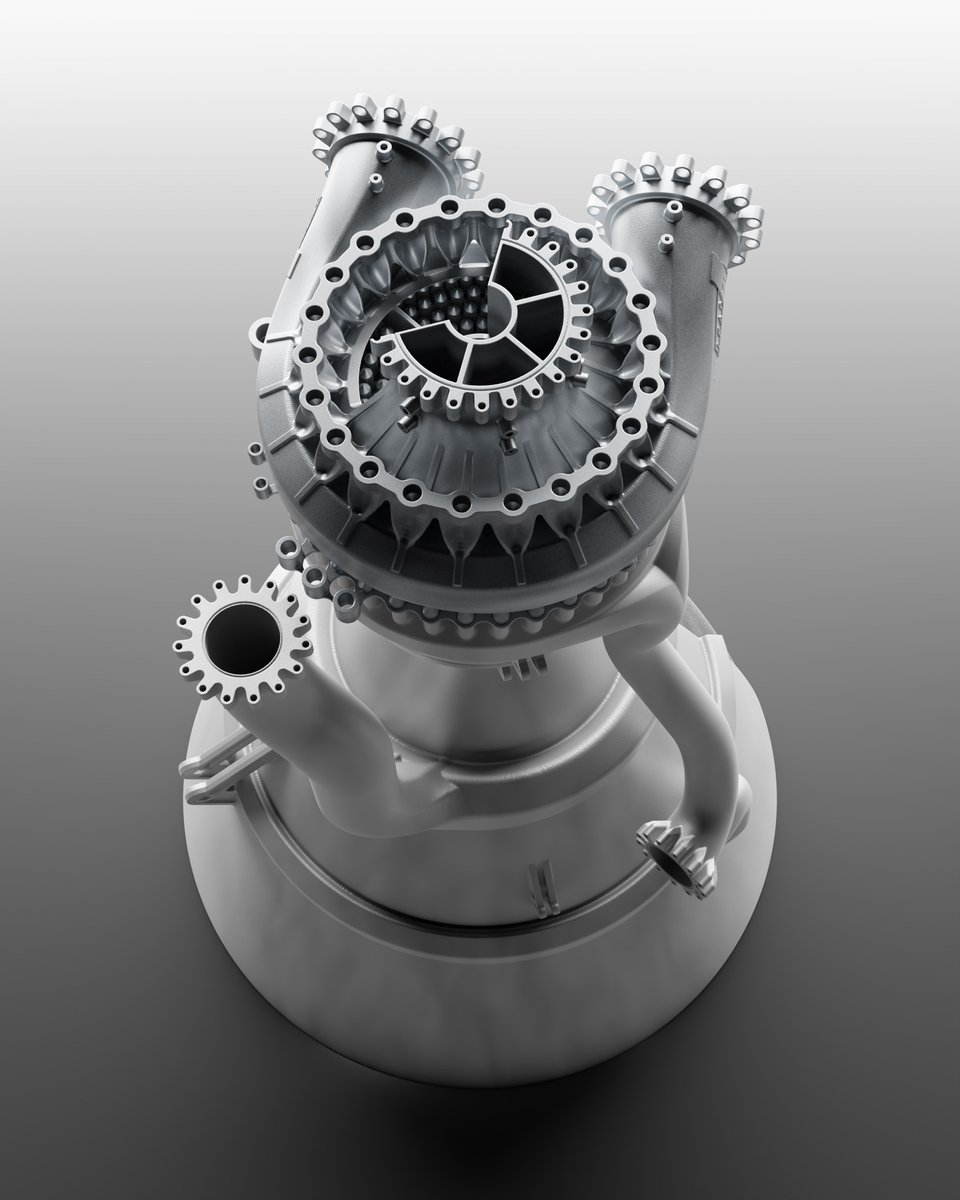

A 28 kN MethaLOX thruster designed by Noyron, our Large Computational Engineering Model. Noyron builds machines from spec to send-to-manufacturing without human interaction and without the use of CAD.

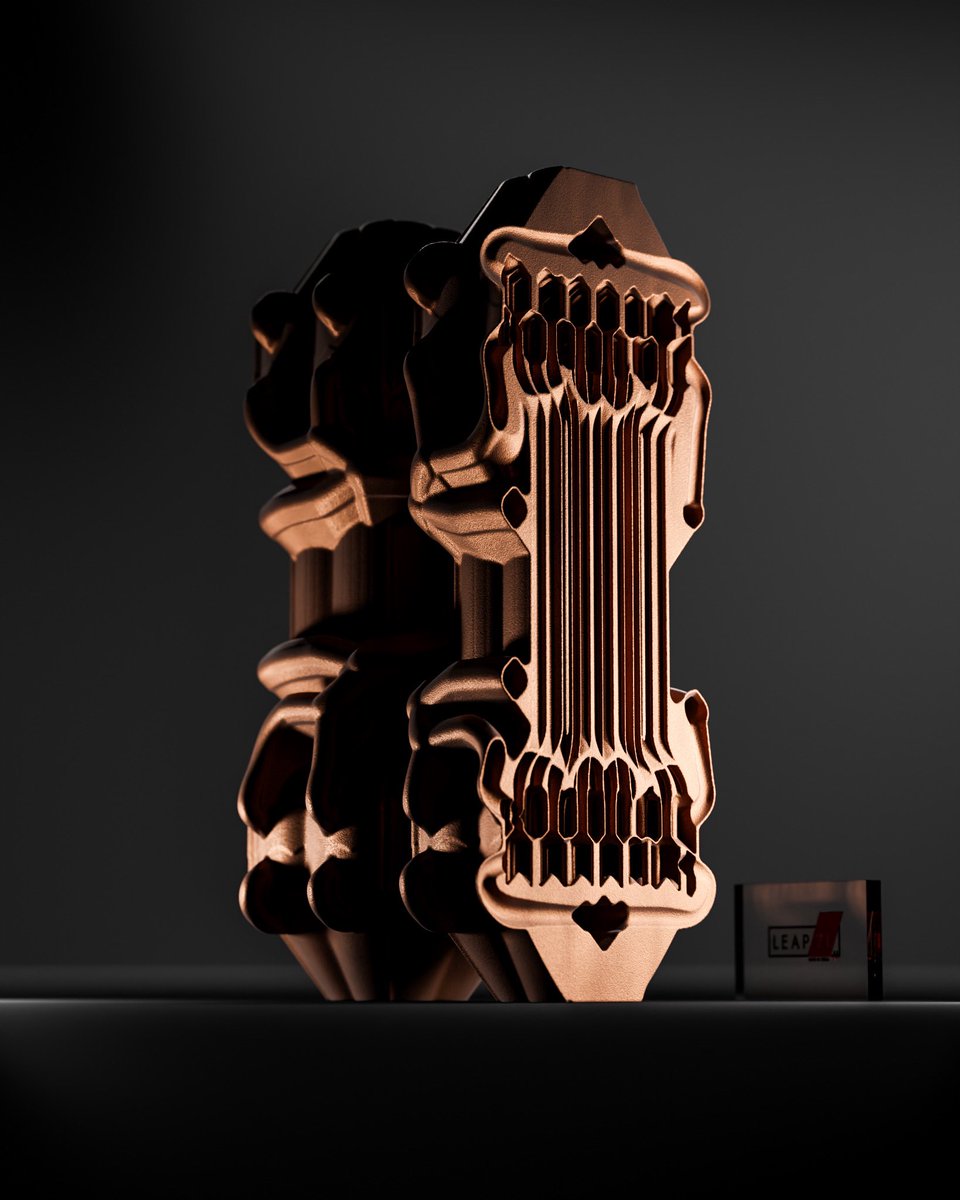

A large stackable water/water heat exchanger designed through the Noyron Large Computational Engineering Model. We can vary the size, shape, and cooling strategy over a vast parameter space.

Assembling a 1.5kN thruster at the test stand. Like all of our rocket engines, this one was created from the same shared DNA, encoded in the Noyron Large Computational Engineering Model. The regen-cooled Kerolox engine was generated without human intervention and 3D printed.

A look from above our 2000 kN reference engine shows the injector head optimized for the inflow of hot gaseous methane and oxygen at the mass flows required to feed the engine. The twin methane inlets are on the side, the GOX inlet in the center. Created by Noyron without CAD.

A lightweight high-performance customizable and stackable water/water heat exchanger for the energy sector designed using the Noyron Large Computational Engineering Model. The inside structure consists of checkerboard-interleaved cooling channels, oriented to be 3D printable.

Rocket engines that don’t fly: We use Noyron to build advanced heat exchangers for our clients in the aerospace, energy, and A/C cooling industries - and beyond.

"AI in engineering" - or not?. I wrote an article about our work at @leap_71 for @MetalAMMag in which I describe our tech stack, why LLMs are (mostly) a bad idea for engineering, and how we finally get J.A.R.V.I.S.