SDT Ultrasound Solutions

@SDTUltrasound

Enabling our customers to better achieve their operational objectives by improving the reliability of their assets.

Ultrasonic #TightnessTesting quickly confirms if a sealed volume is truly sealed. From hatches to vehicle doors, ultrasound pinpoints leaks fast without pressure, gas, or water. #Maintenance #Reliability

#Misalignment, belt slap, and chain drag can go unnoticed. The SDT340 detects friction changes, helping spot issues before failures. #HearMore about #AirborneUltrasound inspection: linkedin.com/pulse/identify…

Thrilled to have participated in the VANZ exhibit this May! Grateful for the connections and community in Australia and New Zealand. #Maintenance #Reliability

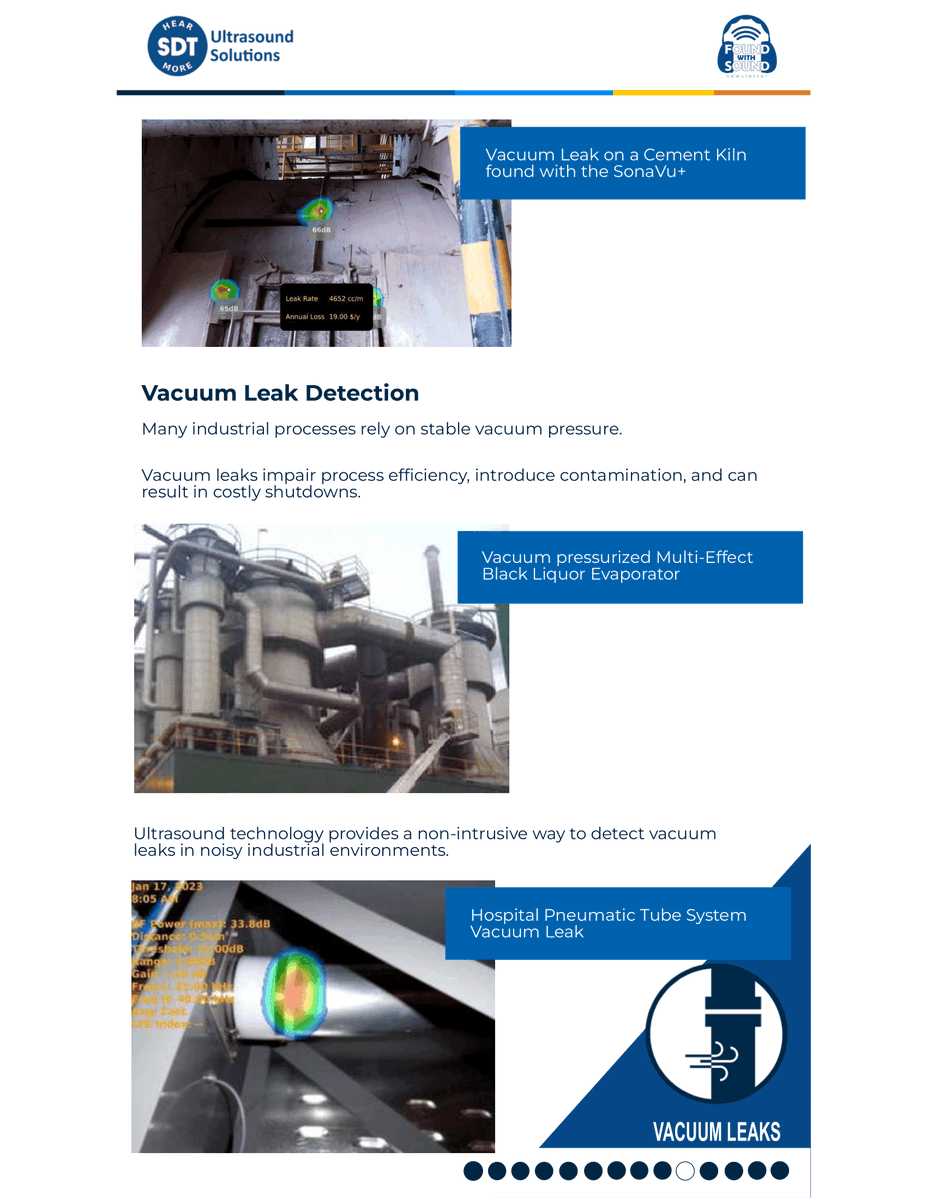

Find #VacuumLeaks Instantly with Ultrasound Monitoring! Detect subtle leaks in real time with minimal disruption. Perfect for any fatory environment! #Maintenance #Reliability

Ultrasound has evolved from a niche tool into a frontline condition monitoring technology, proven effective at detecting mechanical and electrical faults, verifying steam traps and valves, ensuring precision lubrication, and much more. Ultrasound operates in the high-frequency…

Four chain drives powering critical equipment were inspected with the SDT340 and airborne sensor. Ultrasound waveforms revealed everything—from well-lubricated to severely worn. A fast, reliable way to detect damage before failure. Read the case study: linkedin.com/pulse/identify…

Behind the scenes at SDT Ultrasound Solutions: 25+ LUBEChecker kits prepped, packed, and ready to ship. From sensors to hardware configurations, everything’s staged to support #Reliability teams serious about #PredictiveMaintenance.

Luis Vasquez recently delivered hands-on ultrasound training to our offshore oil and gas customer aboard their vessel. This on-site support tailors our training to real-world environments, empowering reliability professionals everywhere! #Reliability #Training #OilAndGas

Can ultrasound readings be taken on a shaking machine? Yes! This video shows the SDT340 with a RS2T magnetic #ContactSensor on a vibrating machine. For #Reliable data, avoid loose surfaces. Tools like the SDT-340 enable #PredictiveMaintenance in difficult environments.

#LeakDetection is only effective when it’s consistent. Ultrasound helps you catch even the smallest leaks, track savings, & prevent repeat issues; all while making wins visible. Build a leak management strategy that lasts. contact us: [email protected]

The Frank J. Horgan Filtration Plant ensures clean drinking water for the Greater Toronto Area with multi-stage treatment from Lake Ontario. To test #Valves for sealing integrity, they use SDT #Ultrasound detectors during installation and while in operation to ensure proper flow

Check out this article from Machinery Lubrication on data-driven lubrication! Domtar’s Meadow Lake Mill switched to SDT’s LUBExpert ON-GUARD for smarter maintenance. Read it here: shorturl.at/W4lQ0

Wishing Gus Velasquez all the best in retirement! After over 20 years at SDT, he made a huge impact on our team and ultrasound #ConditionMonitoring as a whole in Latin America. We are very grateful for his contributions! #Maintenance #Reliability

Catch early signs of #BearingFailure with SDT's heterodyned sensors which detect even the smallest changes in friction or impacting on rotating assets. This can help teams plan #Maintenance in advance and avoid costly #UnplannedDowntime #Reliability #PredictiveMaintenance

#SteamTraps keep your system efficient by removing condensate; preventing corrosion, water hammer & downtime. #UltrasoundInspections quickly detect failed, stuck, or leaking traps so you can take action before problems arise. #Maintenance #Reliability #ConditionMonitoring

Detect electrical faults early with the SDT340. Routine ultrasound inspections help keep assets running properly and prevent costly downtime. #Maintenance #Reliability #ElectricalInspection #ConditionMonitoring

Calendar-based greasing wastes lubricant & leads to over and under #Lubrication practices, ultimately shortening bearing life. Ultrasound devices like the LUBExpert let you grease based on condition — reducing grease use by up to 30%, extending #BearingLife & preventing failures.

During #PulpAndPaper factory shutdowns, steam must be gradually reintroduced to prevent thermal shock and cracks. The #BPFI defect below was detected using the SDT340 after improper steam-up caused a crack on the #Bearing's inner race.

Valves are critical to process control, but failures compromise safety, quality & efficiency. Ultrasound #ValveInspections show health in real time; detecting leaks, blockages & faults without downtime. #Maintenance #Reliability #PredictiveMaintenance #ConditionMonitoring