Power & Motion

@PowerMotionTech

Your source for everything fluid power

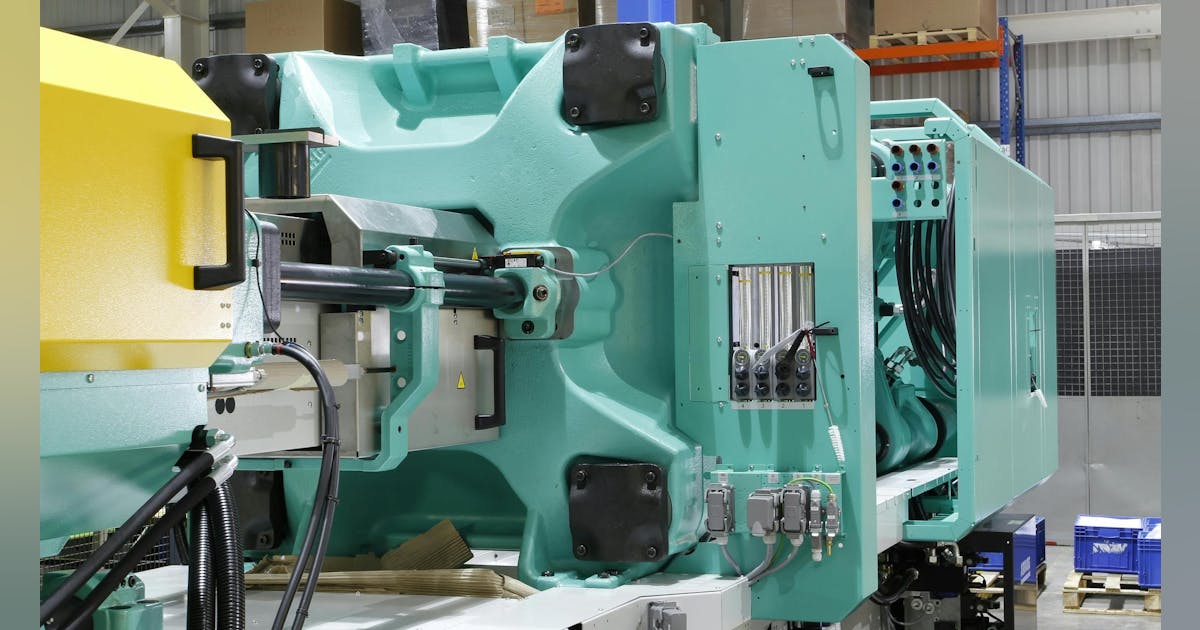

In this article from @REVPART, you'll learn how real-time motion feedback can be used for #prototyping and #injectionmolding. bit.ly/4f3f5fy

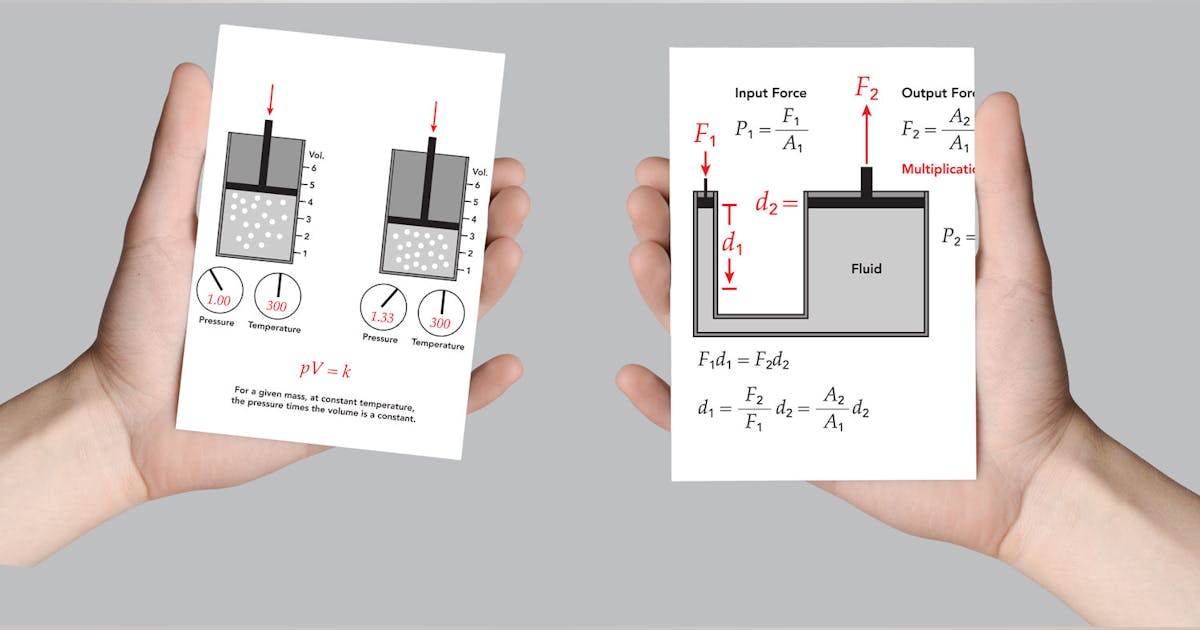

Boyle’s, Charles’, and Pascal’s Laws describe the basic behavior of fluids with respect to volume, pressure, and temperature. Here’s a quick look at all three. bit.ly/3v6ZjtM

There are some technological challenges which must be overcome to make use of solid-state batteries more widespread within the #EV market. See some innovations: bit.ly/44hmceG #electricvehicle #EVbattery

This article from @scanreco highlights how embedding #functionalsafety into every stage of product development—from concept to deployment—not only protects people and equipment but also drives innovation and market trust. bit.ly/4m8EC9m

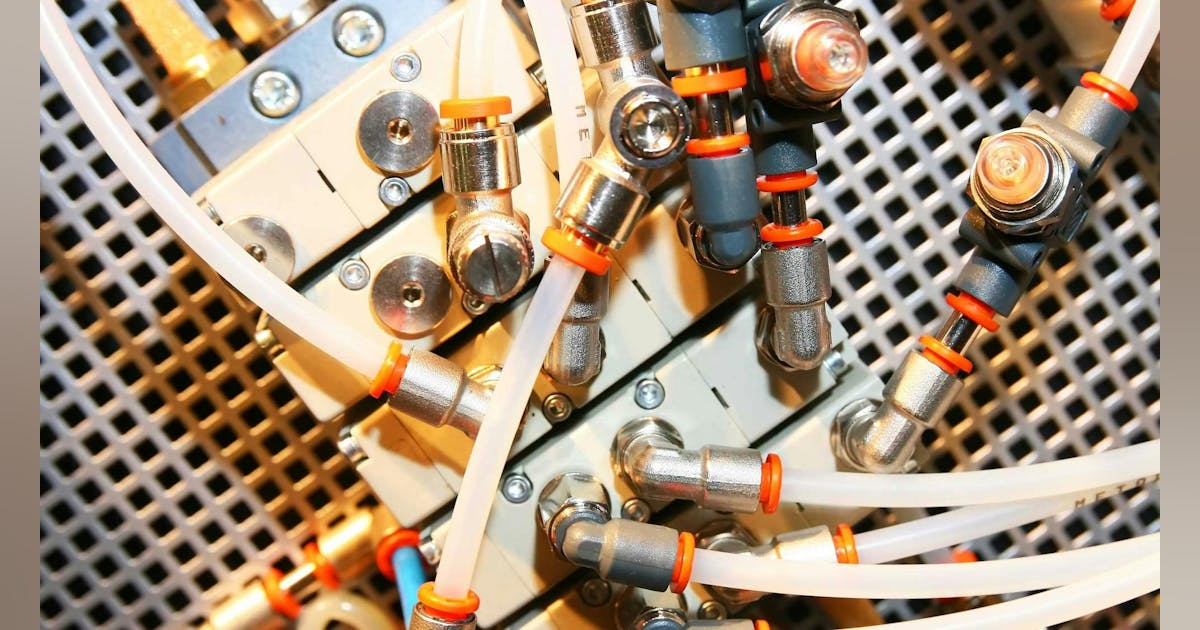

The energy efficiency of pneumatic systems can be improved by evaluating ways to reduce the demand for compressed air. bit.ly/3JtXdv7

Use of #FFKM elastomer materials in #ORings, seals and gaskets can meet the chemical resistance and high temperature requirements of heavily regulated industries. Check out how in this article! bit.ly/3UeqqAr

Take our brief 1-question survey to let us know what topics related to industrial fluid power you'd like to see #PowerandMotion cover. bit.ly/46iomOh #fluidpower

Properly pairing an electric motion platform with digital simulation technologies allows the creation of safer and more accurate flight training devices. bit.ly/3vMcvs3

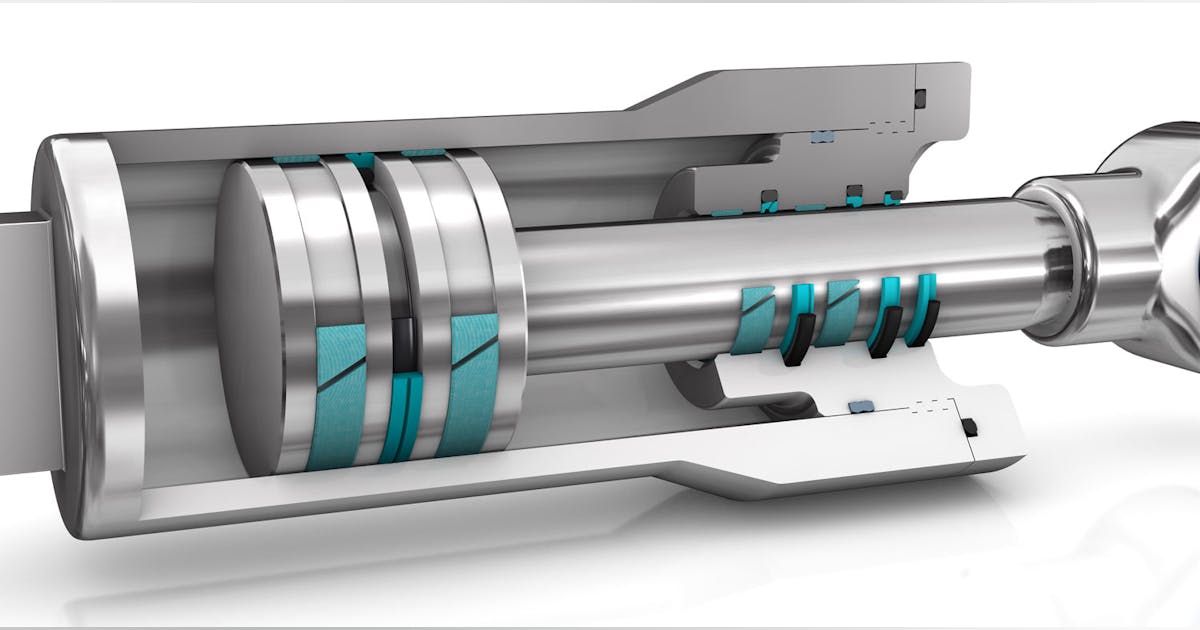

Higher-strength steels not only reinforce hydraulic piston rods against dangerous failures, but yield economic benefits through component downsizing, reduced weight, and cost—without sacrificing safety. bit.ly/3MO9bjr

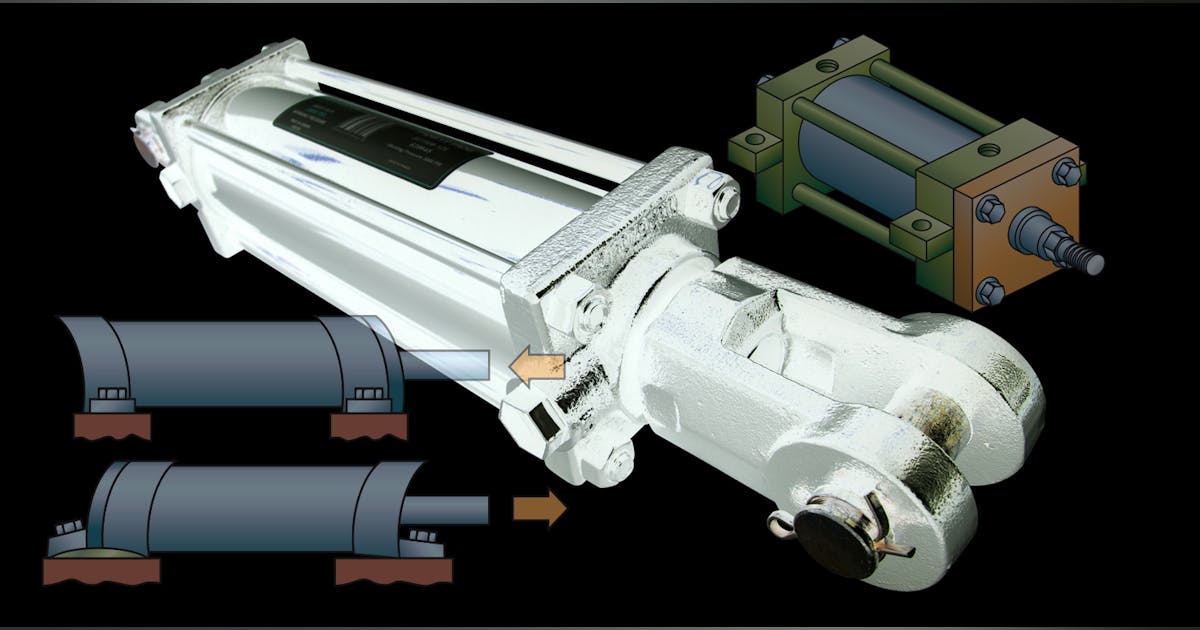

When #hydraulic or #pneumatic systems must produce linear motion, cylinders become their most important component by converting fluid pressure and flow to force and velocity. bit.ly/3MQMBqn

Understanding a #seal’s function isn’t difficult—it keeps fluids in and contaminants out. Understanding how to get this done most effectively in a specific situation is an entirely different matter. bit.ly/3wL0QXV #sealing

Trouble-free use of fluid power cylinders depends, in large part, on properly mounting the component for the particular application. bit.ly/3sXvsmS

To examine and compare the two most common types of buffer seals and the parameters that extend their service lives, engineers developed a test rig that covers all application parameters to get an overview on seal performance. bit.ly/383tha4

Zoned Safety design establishes multiple independent safety zones within a single pneumatic manifold system. bit.ly/3G9aM0v

Because O-rings provide such a simple solution, many designers and technicians take them for granted and may even ignore common sense when using O-ring fittings. bit.ly/4bCgS8s

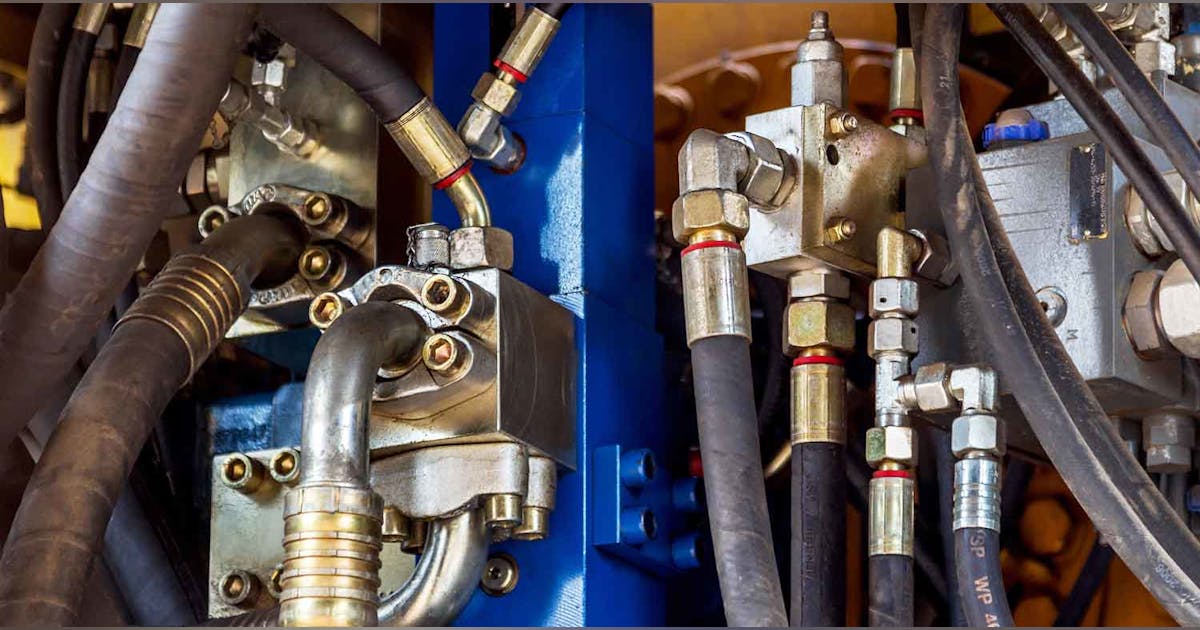

Replacing couplings with the incorrect size can cause unintended consequences. In this article, we'll show you how to calculate flow velocity, a must for replacing a larger hydraulic hose inside diameter with a smaller hydraulic hose inside diameter. bit.ly/3Wa2xrN

Being able to measure the weight of a container or skid in applications such as material handling or crop harvesting is essential to boost productivity. bit.ly/3K6dSVX

In this article, we’ll discuss some #pneumatics #rail applications and their corresponding international standards. bit.ly/3K5GIpf #railway

This gallery showcases the latest #sensor technology developments & the benefits they can bring to #hydraulic, #pneumatic, & #electromechanical systems. Featuring tech from NewTek, Baumer, @POSITAL_FRABA, @Saelig, @NovotechnikUS, @eatoncorp & Rota Limited. bit.ly/3TBpNQu

Tests reveal how these two seals interact to affect friction and seal life. But first, a look at buffer seals. bit.ly/3waSgkV