Andy Rawson

@AndrewRawson11

Andrew Rawson's Musings.

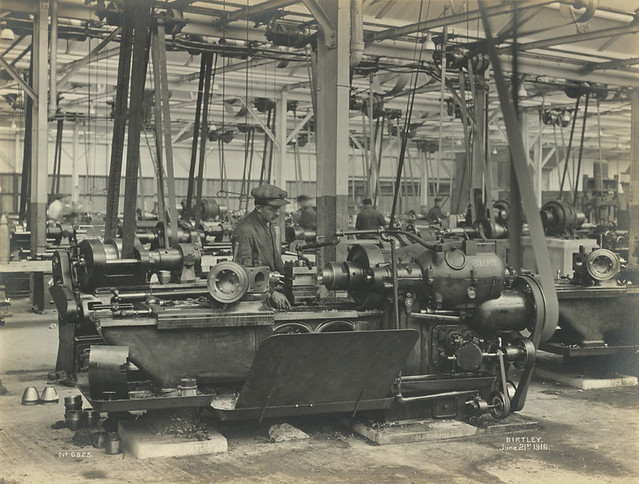

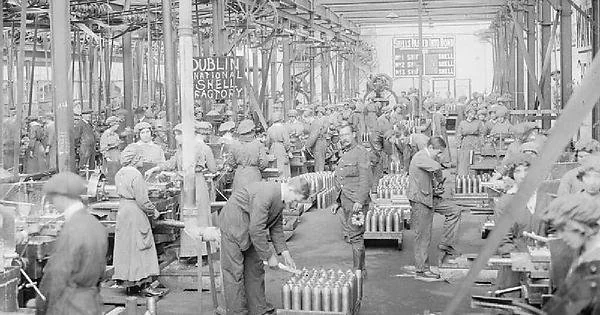

Large calibre shells were made in National Projectile Factories. They were also housed in purpose built factories and run by experienced armaments companies. They were equipped with specialist equipment, while the weight of the casings meant that they were mainly manned by men.

Most towns and cities opened National Shell Factories in existing buildings. They were set up to make small calibre shells for field guns using spare lathes. They employed around 80 per cent women because the parts were small and light. The men were the mechanics and overseers.

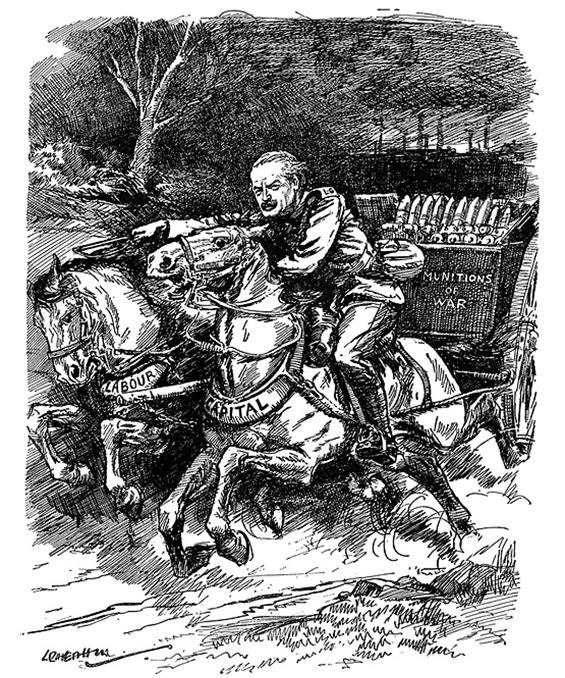

In the summer of 1915, the Ministry of Munitions got each town and city to appoint a Committee of prominent citizens. They located the companies, premises, equipment and labour. They appointed a Board of qualified industrialists who organised them all to make shells.

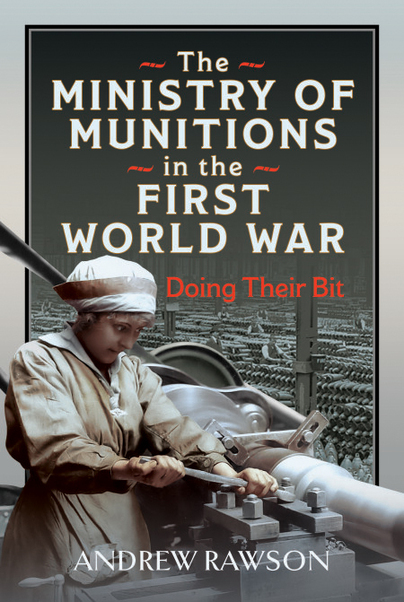

The BEF needed millions of shells to conduct an offensive and they were complicated items. Several types of factories were set up to make the various elements and assemble them. Most of the work ended up being carried out by women. My book explains how they worked.

My son has found his g-g-g-uncle's name, William Rawson, on the Menin Gate.

The ending of Planet of the Apes where Charlton Heston realizes it was Earth all along remains one of the most iconic twists in film history.

What movie had an ending so good you thought about it forever?

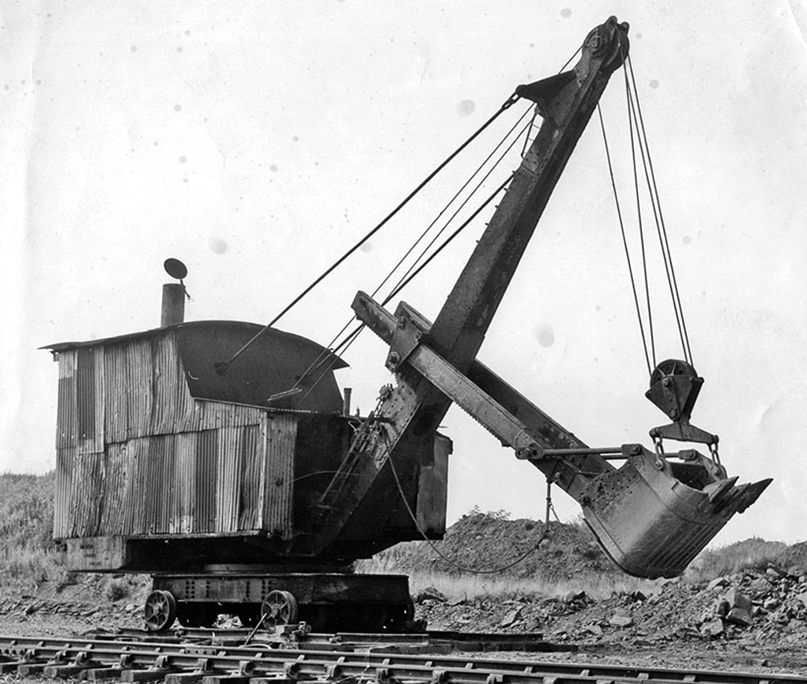

21 million tons iron ore a year was required to make the steel for munitions during WW1. A lot came from Spain, exchanged for coal. Steam shovels helped 250,000 miners (some of them prisoners of war) dig it in Britain, some at the coastal Hodbarrow mine in Cumbria.

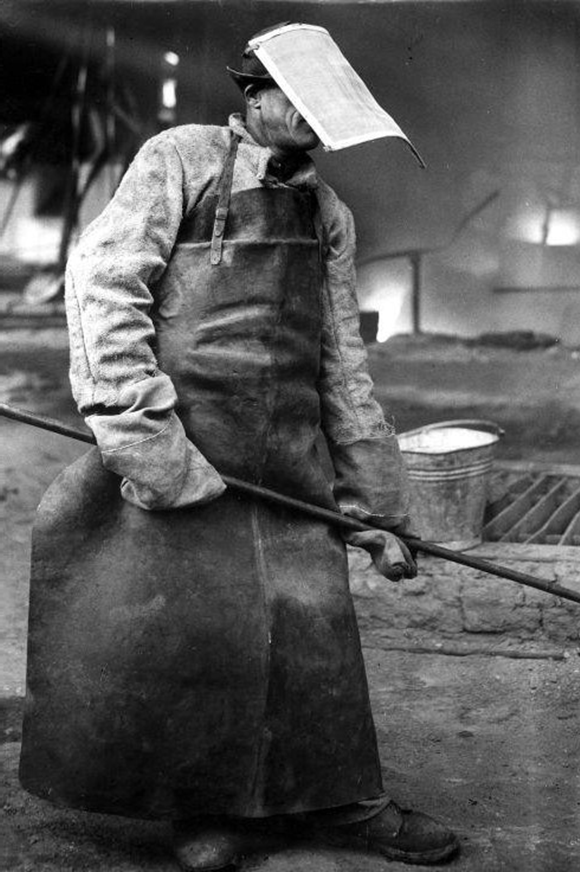

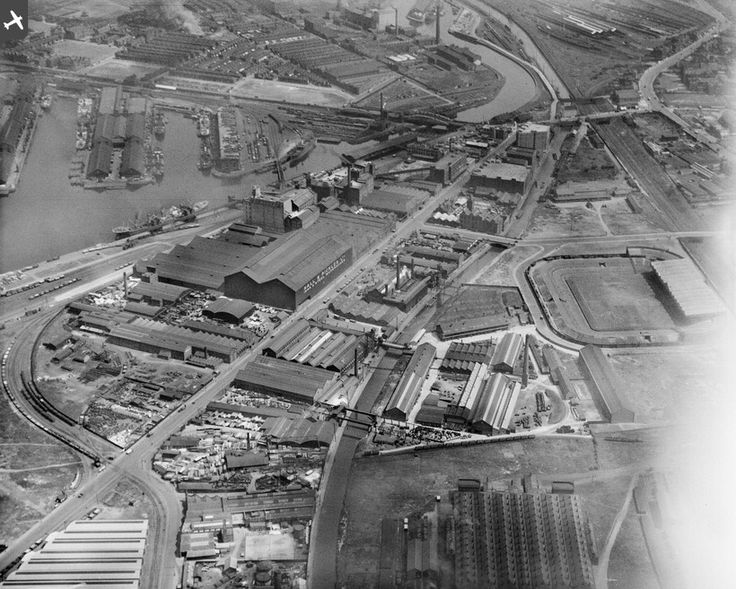

Munitions required steel. Men worked in the foundries or made the larger items, while women made the smaller ones. Furnaces were expanded to increase output, while thousands of tons were imported from America to Trafford Park, Manchester.

The Ministry of Munitions was formed after the disastrous battle of Aubers Ridge on 9 May 1915. The BEF was short of shells and industry could not make enough. So, the Lloyd George was appointed its head, with instructions to harness industry with the help of business leaders.

#MeetTheAuthor 👋 Here's @AndrewRawson11 showing his brand new release: 📖 The Ministry of Munitions in the First World War – Doing Their Bit, out now! 🛒 buff.ly/u76ymue

A call to stop making luxury goods at the start of WWI, meant many factories closed down. That meant a reduction in coal demands and 200,000 out of 1.1 million miners were laid off. Many enlisted and coal stocks ran short. Check out @BElliottAuthor book pen-and-sword.co.uk/Miners-and-the…

Check out this article I put together which summarises the problems faced trying to get enough workers for the munitions factories in WW1. Stay cool and have a great weekend! pen-and-sword.co.uk/blog/manning-t…

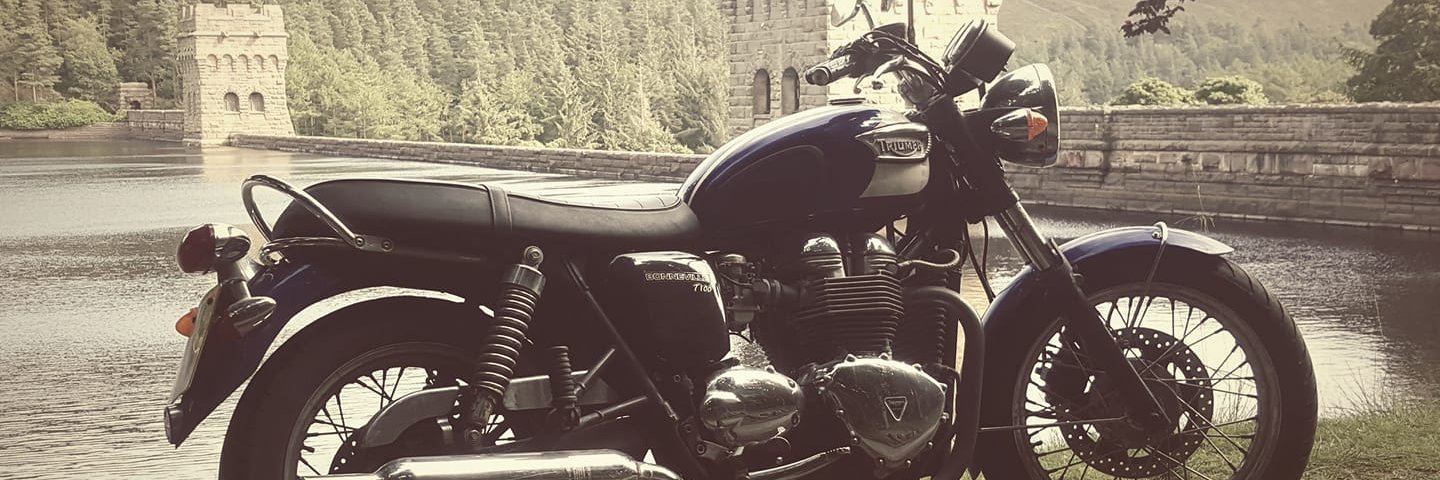

Derwent Reservoir where 617 Squadron practiced for the Dambusters raid.

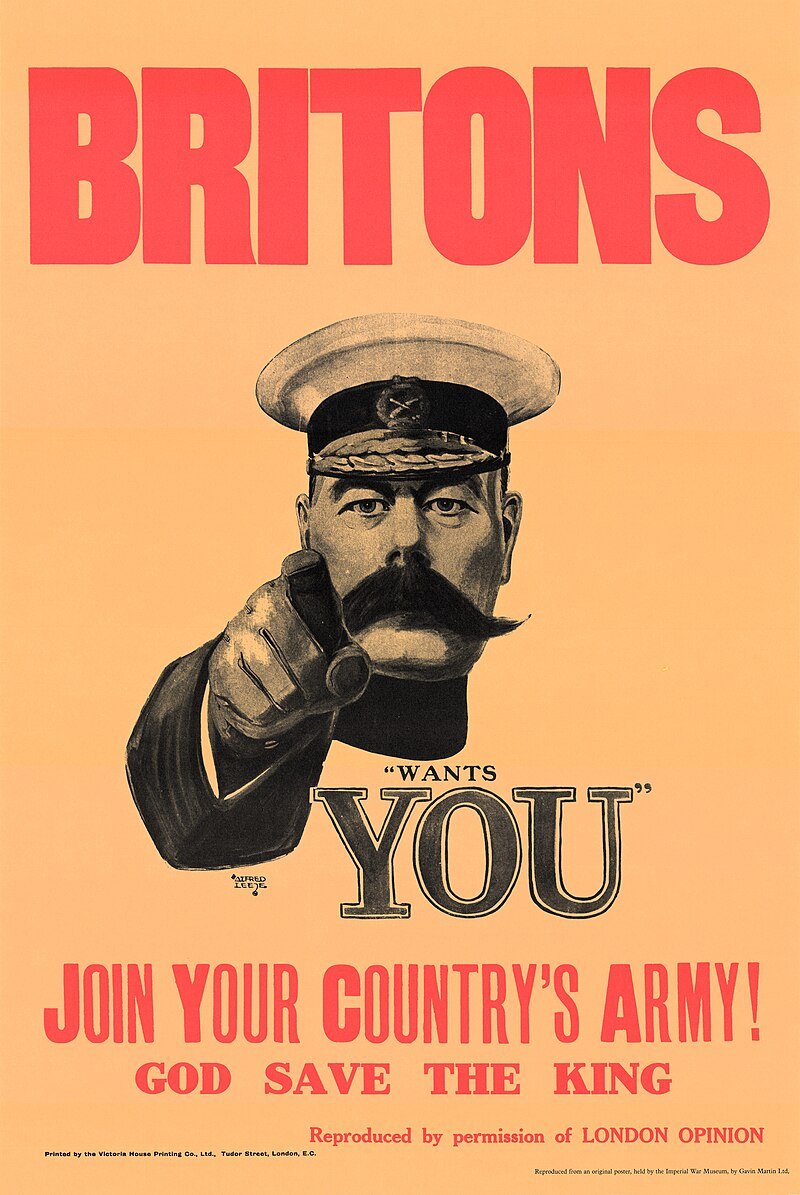

At the start of the WW1. Field Marshal Kitchener said 'Your Country Needs You'. He should have added in the armed forces and the munitions factories because the New Armies had few weapons and no uniforms for months. The problem culminated with the shell crisis in May 1915.

My great granddad lost two brothers in 1915. Many visit the Menin Gate in Ypres where soldier Bill is remembered. But few visit Southgate colliery memorial where coal miner Jim is remembered. Without coal you can't make steel and you can't make armaments. Both did their bit.